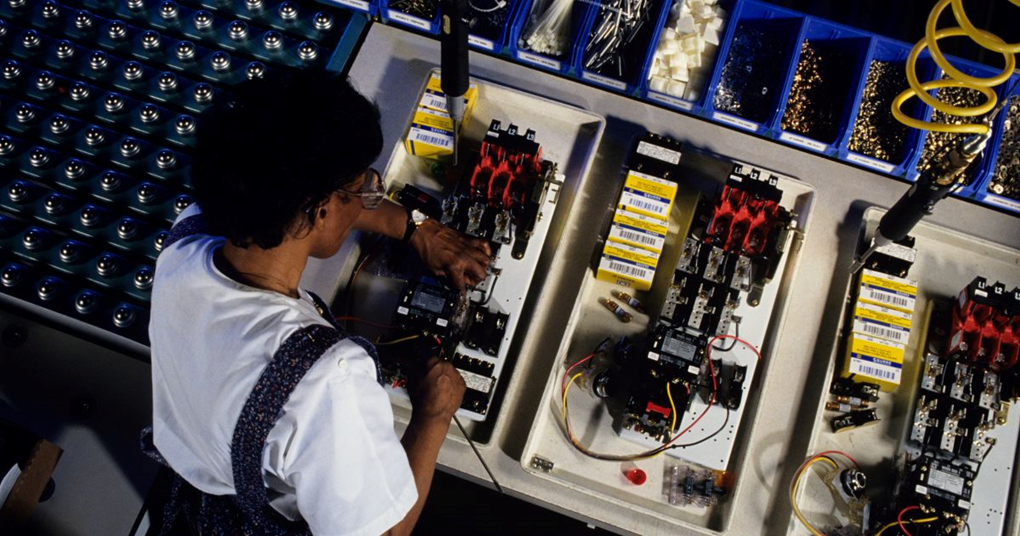

Creative Hi-Tech: Electronics and Leading PCB Assembly Manufacturer

Creative Hi-Tech delivers advanced PCB assembly solutions with a focus on quality, speed, and innovation, trusted by industries like aerospace.

Having a place that gives you the best PCB (Printed Circuit Board) you want for your home is the right feeling that you won’t want to trade.

Searching for leading PCB assembly services in Chicago and Illinois? Then, look nowhere else than Creative Hi-Tech.

Creative Hi-Tech, a leading provider of custom PCB design and assembly in Illinois.

Since our point of beginning in 1998, to this day, we have served customers with the highest quality PCBs.

Our creativity ensures the production of high-quality, cost-efficient PCB assemblies that meet diverse project requirements.

We specialize in quick-turn assembly services and offer a full range of solutions from PCB prototyping to both low and high-volume production.

Circuit board assembly is our specialty.

We pride ourselves on our quality as an electronics contract manufacturer in Chicago, as well as our ability to tackle any type of circuit board manufacturing project.

Creative Hi-Tech has the knowledge and the right people to get the job done right the first time.

Before we talk more about Creative Hi-Tech, let’s go into the Printed Circuit Board (PCB) and what it entails.

What is a Printed Circuit Board (PCB)

Printed circuit boards, also known as PCBs, are the electronic boards used in most electronic devices.

They are used in nearly all modern consumer electronic devices and accessories, including phones, tablets, smartwatches, wireless chargers, and power supplies.

Type of Printed Circuit Board (PCB)

- Single-sided

- Double-sided

- Multilayer

- Rigid

- Flex

- Rigid-flex

We will explore each of the six types of printed circuit boards and their applications below.

Single-Sided PCBs

Single-sided PCBs are the most popular choice of electronic manufacturers.

These affordable and easy-to-build boards are made from a substrate, which is the material that holds all the board’s components.

One conductive copper layer is added above the substrate.

As simple as nature can be, single-sided PCBs are used in basic applications such as calculators, electronic toys, and timing circuits.

Advantages

- Cost-effective

- Easy to manufacture

- Suitable for low-density designs

- Easy to repair if something goes wrong

- Easy to design

Double-Sided PCBs

Double-sided PCBs feature is of two conductive layers, one on the top and one on the bottom of the board.

Holes are drilled in the PCB to allow metal components to connect the circuits on either side of the board.

Cell phones and amplifiers are examples of Double-Sided PCBs.

Advantages

- More flexible

- Increased circuit density

- Suitable for advanced electronic systems

Multilayer PCBs

Introducing at least three conductive layers, multilayer PCBs are proper for more complex electronic devices.

Each conductive layer is sandwiched between insulating sheets and is bonded and laminated together.

These PCBs tend to be on the smaller side but pack a powerful punch.

Multilayer boards are often used in computers, tablets, and medical equipment.

Advantages

- Compact in size

- More robust

- High level of design flexibility

- Suitable for high-speed circuits

Rigid PCBs

Rigid PCBs feature an inflexible substrate and cannot be twisted, bent, or folded, and they can be single-sided, double-sided, or multi-layered.

X-ray machines, MRI systems, and GPS equipment are examples of Rigid PCBs.

Advantages

- Cost-effective

- Ease of diagnostics & repair

- Low electronic noise

- Ability to absorb vibrations

- Compact

- Lightweight

Flex PCBs

Flexible printed circuit boards are a rising favorite due to their ability to be bent, twisted, or folded to fit their electronic device.

Rather than placing printed circuits and electronic components on a rigid substrate, these elements are placed on a flexible one, mostly a conductive polyester film.

It can be single- or double-sided as well as multi-layered and is used in automotive applications, medical devices, and cameras.

Advantages

- Save space

- Eliminate connectors

- Thermal management

- Increase reliability and repeatability

- Provide uniform electrical characteristics for high-speed circuitry

- Suitable for applications where high signal trace density is needed

Rigid-Flex PCBs

These hybrid PCBs feature the best of both worlds. Flexible yet rigid, these circuit boards are designed and built in 3D.

This enables them to be tailor-made for the device.

They are also lighter as they don’t require connectors.

Aerospace and medical devices are examples of Rigid-Flex PCBs.

Advantages

- 360-degree bendability

- Reduced space requirement through 3D ability

- Shock resistance

- Increased reliability

- Light weight

- Fewer solder joints assure higher connection reliability

- Simplified Printed Circuit Board assembly processes

Components of a Printed Circuit Board

Now, let’s talk about the components of a PCB.

- Traces – Conductive pathways that connect board components.

- Pads – Areas of exposed metal on the printed circuit boards where components are soldered.

- Vias – Holes filled with conductive material connecting traces on different PCB layers.

- Silkscreen – Printed markings on the board surface, including component labels, reference designators, and other information.

Each of these components is essential for ensuring everything is connected and appropriately labeled.

Benefits of Printed Circuit Boards

1. A Compact Solution

A printed circuit board can contain a number of parts and elements.

Because they utilize copper tracks rather than actual wires, it allows for the same types of results without using current-carrying wires.

The boards are smaller, and they are not as bulky.

This is one of the reasons that so many different types of electronic devices are smaller than they were in the past.

The PCBs have helped to push technology forward in a number of different ways. It’s now possible to have highly complicated circuits in very small packages.

2. Saving Time and Energy

One of the best benefits of using printed circuit boards is the amount of time that can be saved.

Connecting components traditionally takes a lot of time, whereas the circuit board will take far less time to assemble once the design is complete.

The design phase is often what takes the most amount of time with printed circuit boards, but even this can be reduced when using the right type of software for its creation.

3. No Loose Connections

The connections in the printed circuit board are made through the copy tracks, and as long as they have been manufactured properly, you are not going to have to deal with short circuits or loose connections.

Compare this to other methods using actual wires, which could become loose when the board moves.

4. A Reliable Option

It’s no accident that so many companies and individuals today are making use of printed circuit boards.

They are a reliable solution that can work for a wide range of uses and products, both large and small.

They can last a long time when they have been made properly, which will give people more confidence in the electronics they are using.

This is true whether that device might be a phone, a computer, or a military-grade piece of equipment that is used in a less-than-forgiving environment.

5. Low Costs

Of course, when it comes to creating and manufacturing various types of electrical goods, the cost is very important.

Fortunately, once the circuit board has been designed and tested to ensure that it is working properly, mass production is very affordable.

There are fewer components being used in most cases, which helps to reduce the cost to an affordable level for most companies.

Conclusion

As we have talked about PCBs, we should also know that electronic devices depend on PCBs since they hold their internal components together.

PCB manufacturers have been heavily investing in further improving their products.

With a wide range of engineering and design capabilities.

We, Creative Hi-Tech, ensure complete security for your PCB design project, from initial concept to final delivery, giving you peace of mind throughout every phase of development.